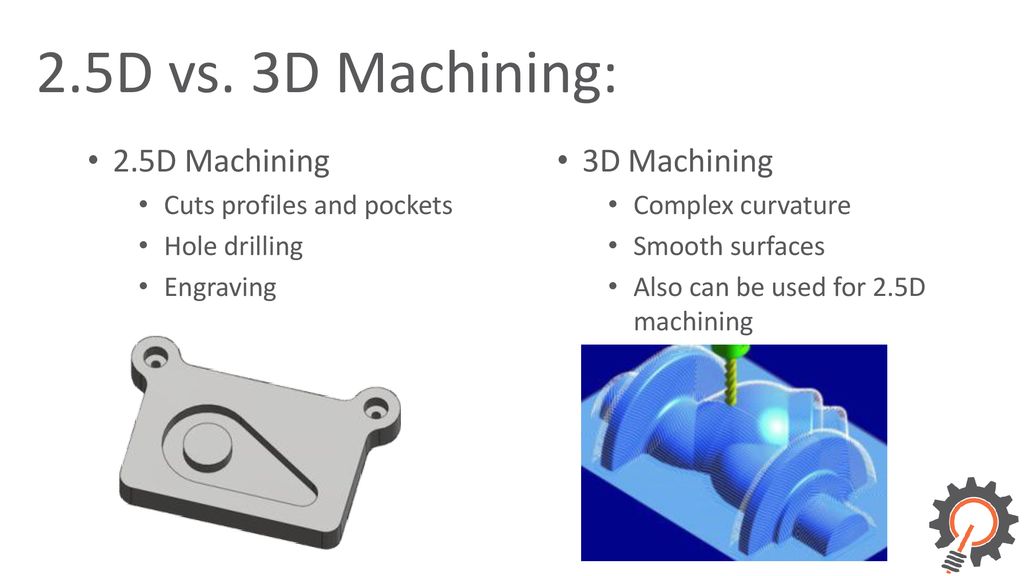

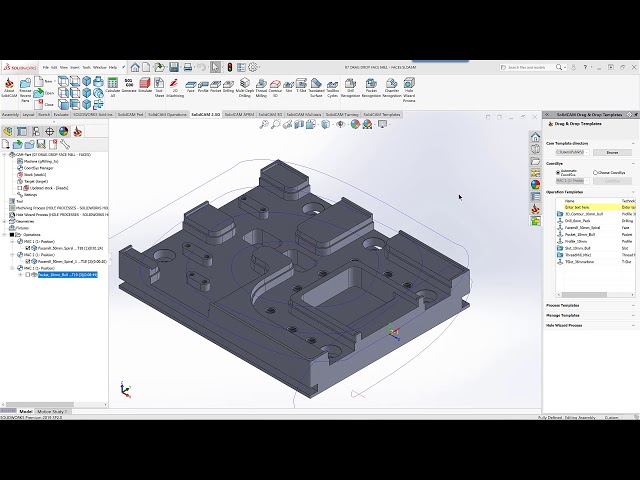

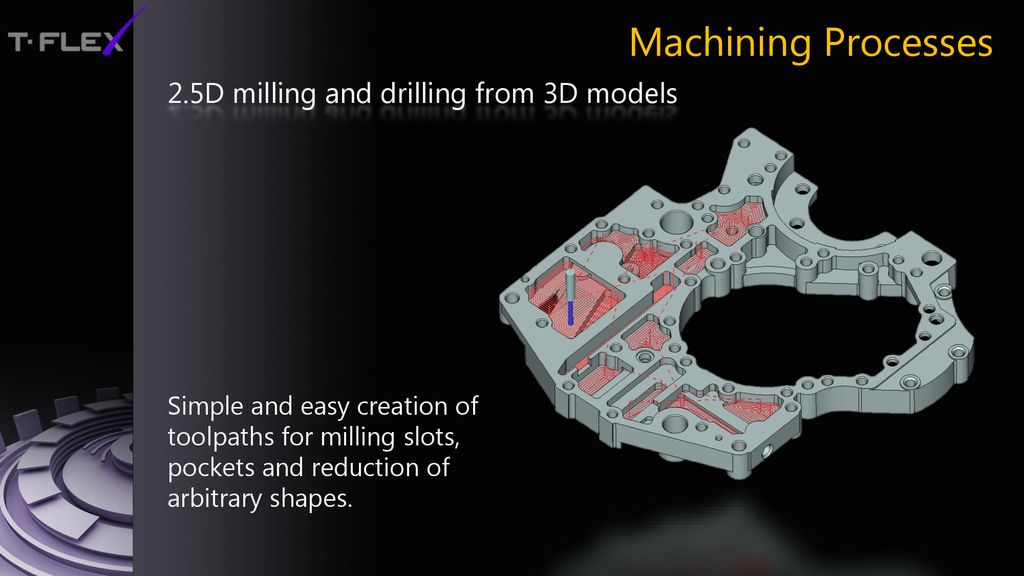

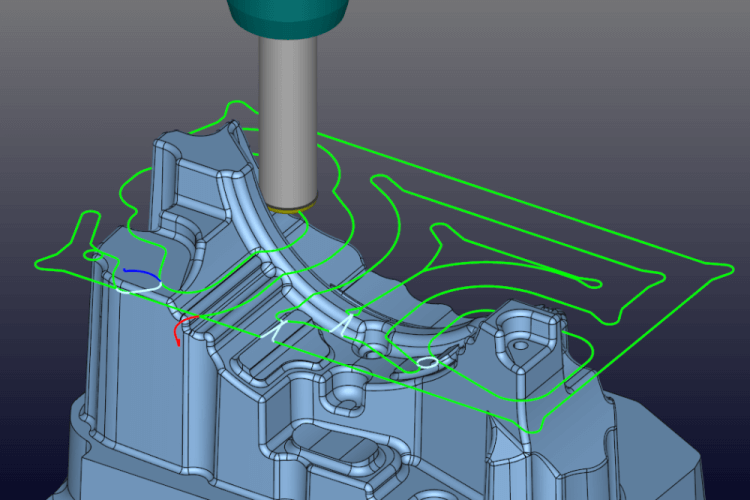

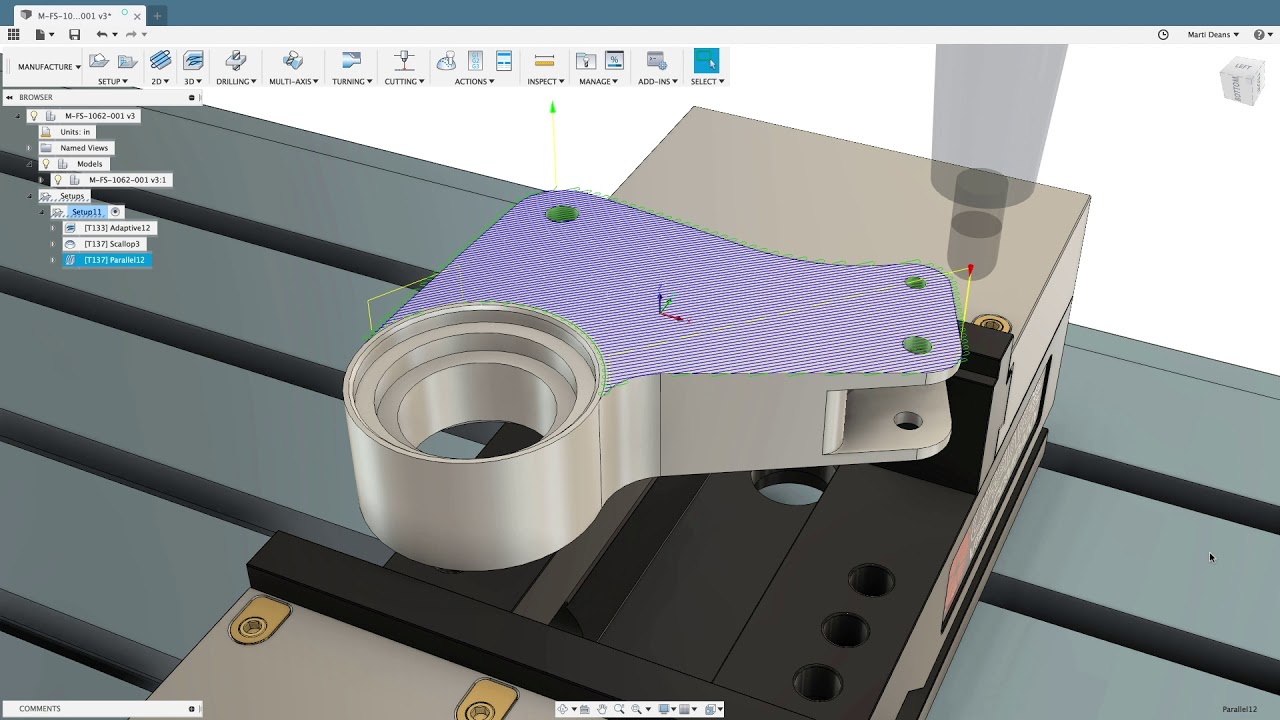

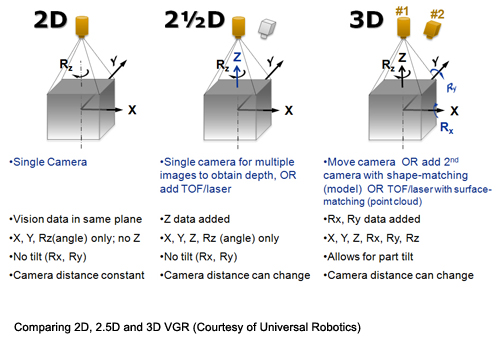

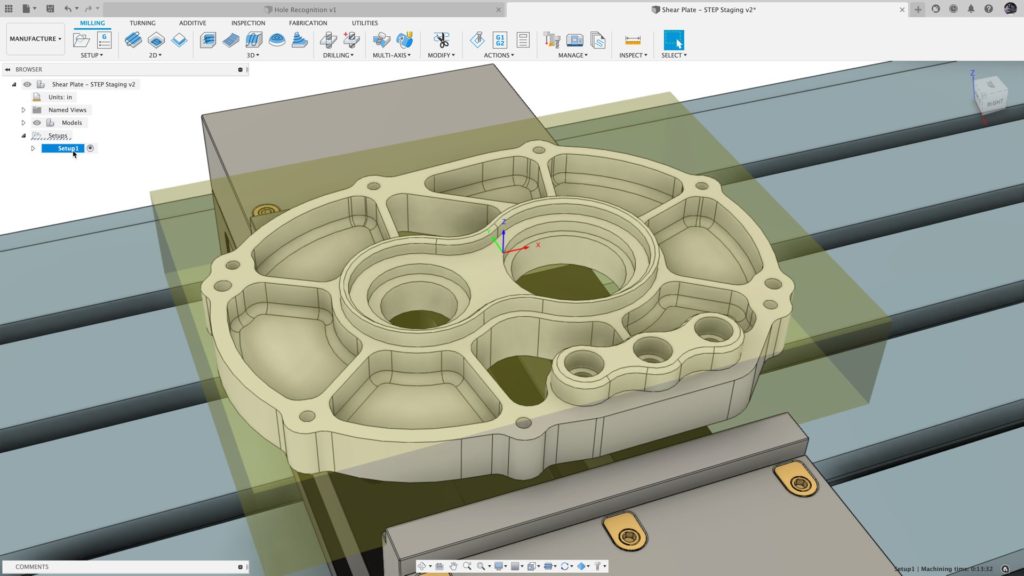

Difference between 2d, 25d, and 3d features, and milling One of the main limitations of this machine is that it is not capable of making true 3d features It is designed to make 25d features that are common to PCBs It does this by taking a 2d sketch (a dxf file) and then sets a depth for each of the shapes captured in that dxfWith "2D chamfer milling on 3D model", component edges with and without modelled chamfers can be deburred safely, inGibbsCAM 25D Solids includes the Profiler, an innovative interface that interactively defines features like bosses, slots, and pockets Unlike automatic feature recognition, the Profiler gives you complete control over the geometric elements that are included in a feature The Profiler can also derive geometry interactively for machining

Week 10 Cam Itp Fabrication

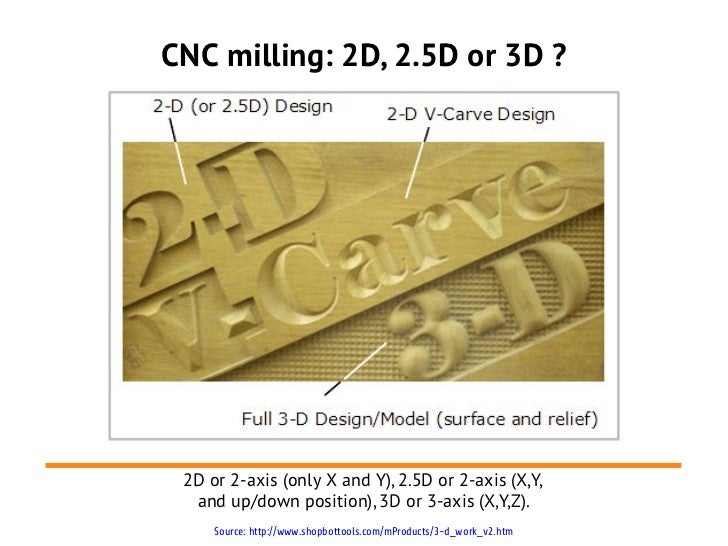

2.5 d vs 3d milling

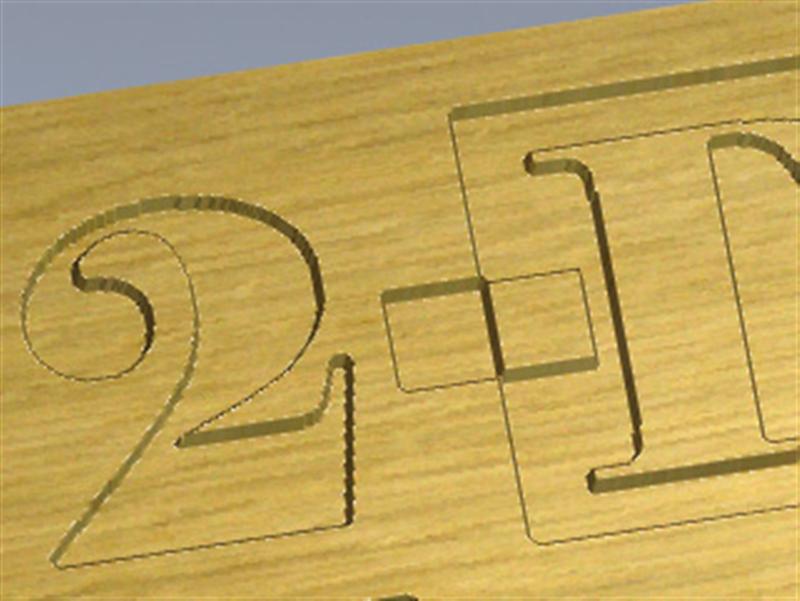

2.5 d vs 3d milling- An object milled in this way is referred to 25D, since it was produced using only 2D tool paths and depths for each area to be milled Another type of 25 cutting is the Vcarve This is a process by which a V shape is engraved, creating a 3D profile in the objectSolidCAM puts the most powerful 25D programming solution at your fingertips, right inside your CAD systemSolidCAM looks, feels and performs like your existing CAD systemIn addition to its powerful 25D milling Profiling, Pocketing and Drilling operations, SolidCAM's 25D module includes Simplified geometry selection using CAD sketches, autofeature recognition and

2 5d Cnc Mill Youtube

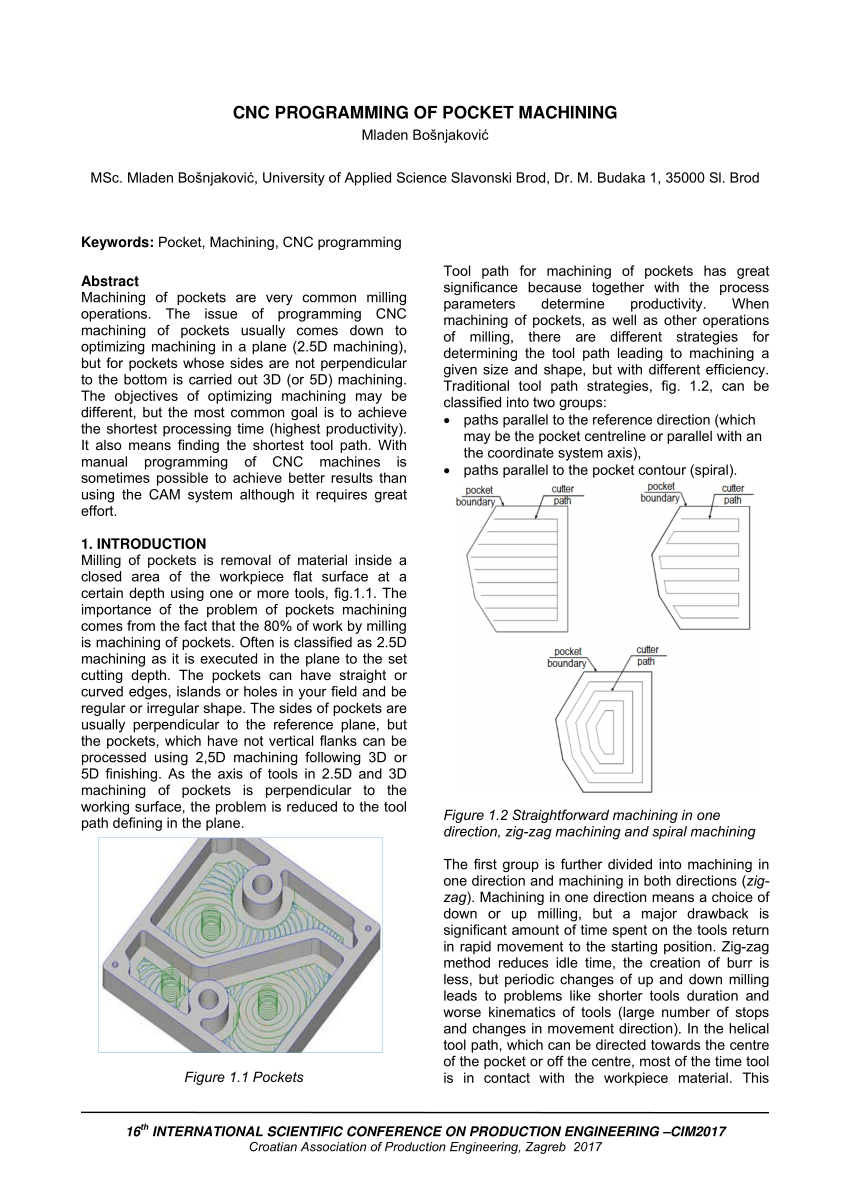

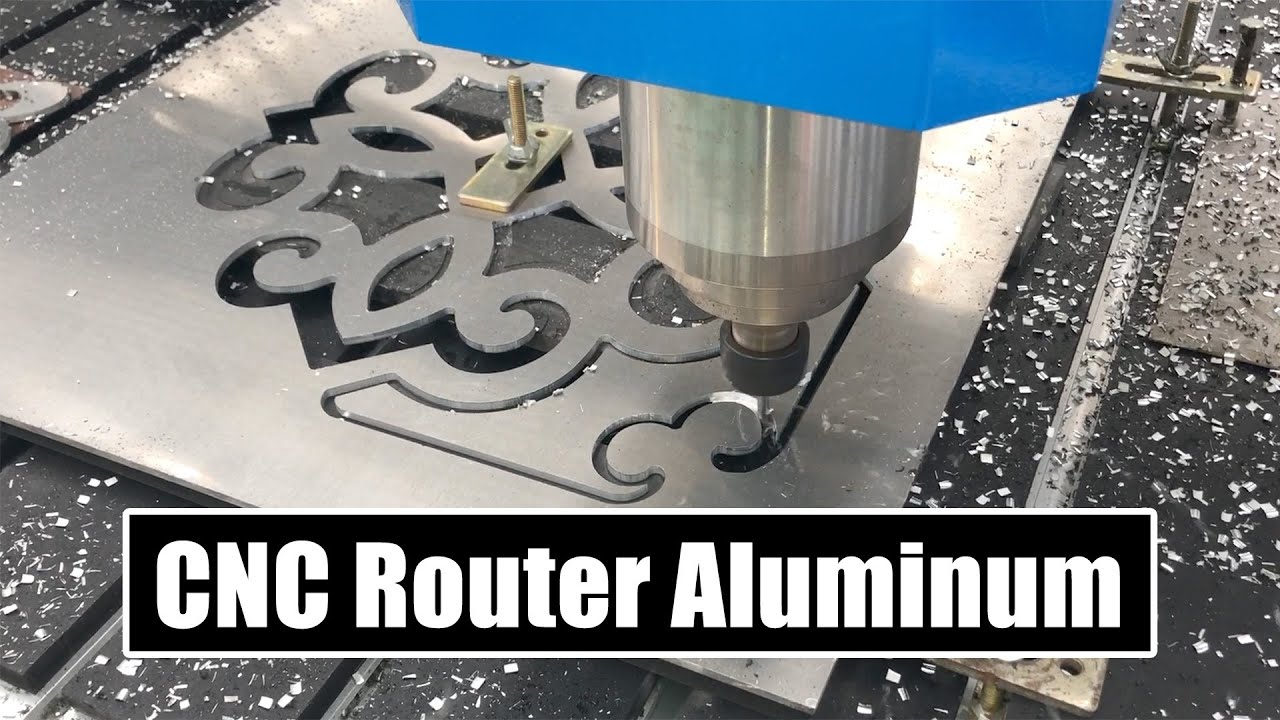

Post Thanks / Like Likes (Given) 31 Likes (Received) 98 25d means you don't have simultaneous control of all 3 axes You can move X and Y simultaneously but Z must be moved in a separate block 2d means your moving Z with a hand crankSo in this case the '2' and the box around the 'D' are carved out to 3mm with a flat endmill The endmill will do a raster of moves and cleans the edges, but stay's cutting at the same 3mm depth If the '2' was at 3mm depth and the box at 4mm depth it would of course still be 2D, but it would be 2 toolpaths 2D toolpaths take some time, if you Topdown milling is referred to as 25D milling because it is more than 2D but can't produce a complete 3D image like say, a horse figurine because it can't reach under the belly True 3D carving generally requires a 5 axis machine with sufficient articulation to

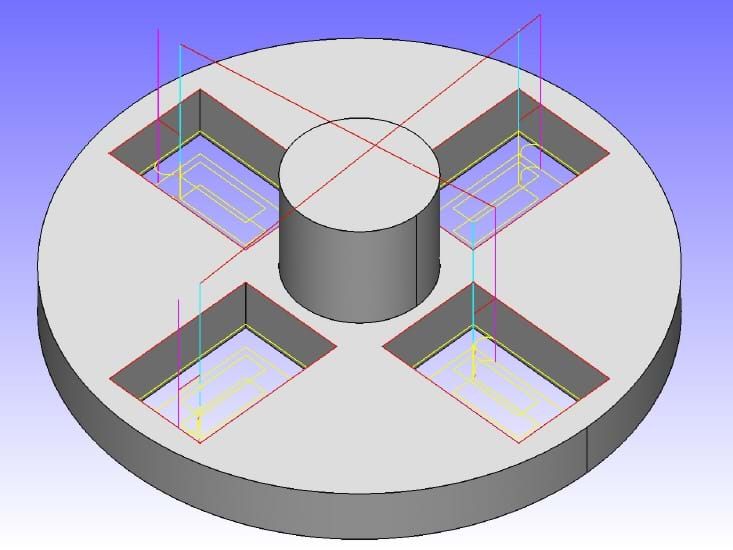

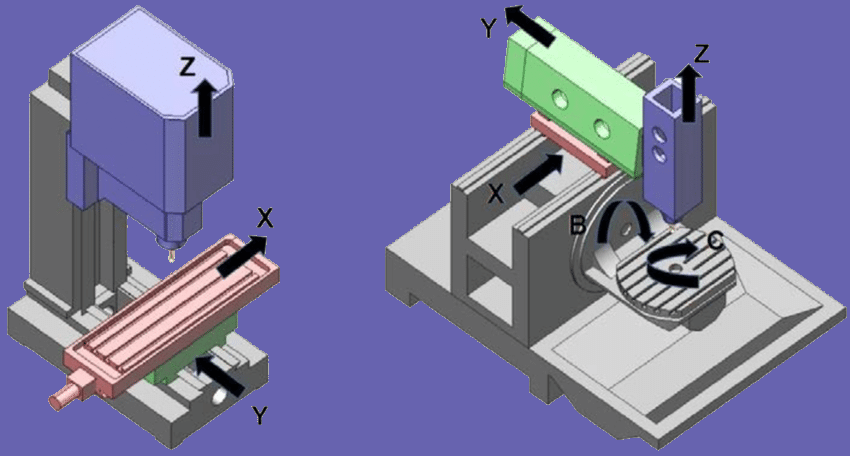

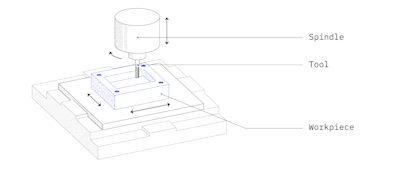

There is no such thing as a half dimension, so the term 25D is really a nonsense term, and has no intrinsic meaning That said, 25 is "somewhere between" 2 and 3, so 25D generally means somethingLiFuJunDong 4 Axis USB CNC6040 Router Engraving Machine 3D Milling Machine w/Controller 110V 15KW VFD WaterCooling Router Engraving Machines for Metal, Wood, Glass and Plastic (6040 15KW 4AXIS) 46 out of 5 stars 7 $1, $ 1,380 00 Only 15 left in stock order soon With 25D milling, there are multiple features on the workpiece This uses the X and Y axes for the toolpath as well as the Z axes, where there is a difference in depth or features on the workpiece With 3D milling, the three axes can cut to different depths, and create different shapes

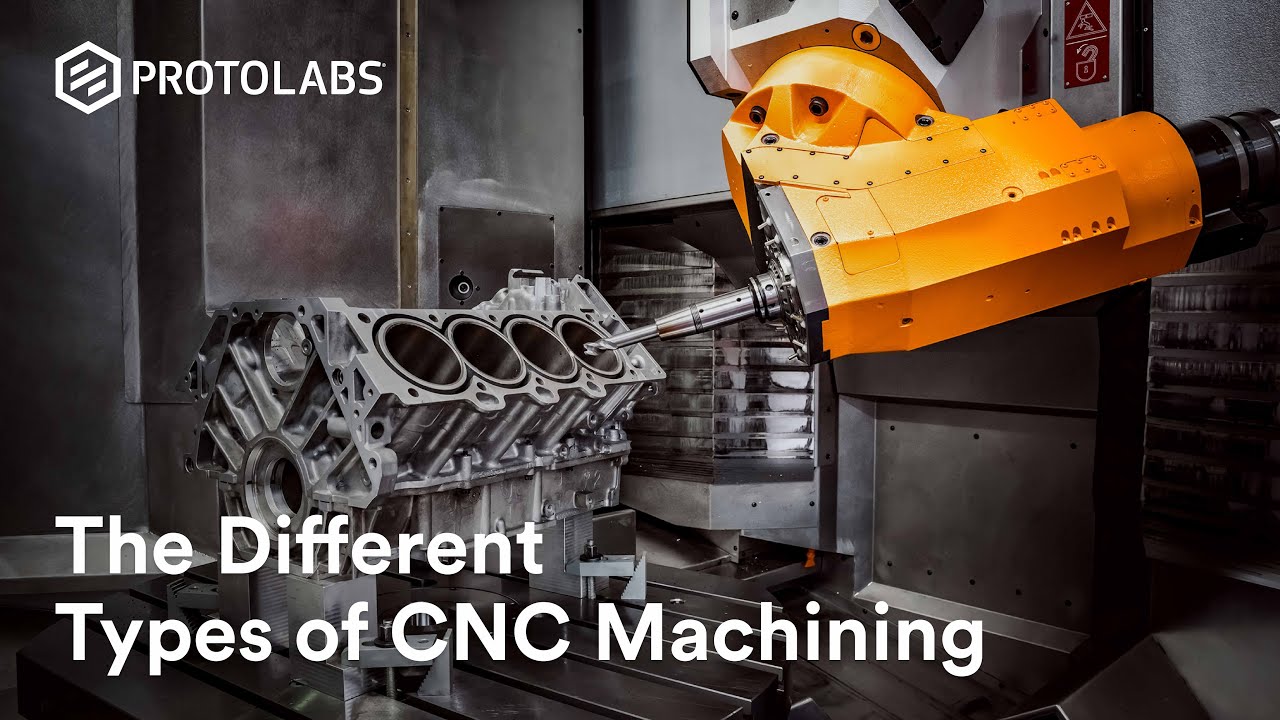

Powerful 3D Machining for Simple and Complex Components OneCNC software offers powerful and precise functions for 3D milling OneCNC enables the production of simple and complex components with highquality surfaces generated quickly, reliably and efficiently Numerous strategies for roughing and finishing ensure efficient 3D machiningThis cutting head is available for 2D, 25D or 3D cutting What are the differences between these three ways of water jet cutting? Rhino would be overkill if you are working with a 25D mill Rhino is powerful for designing complex 3D shapes but its not so hot for 25D designs as it takes a lot of rework when you need to make design modifications and its human interface is fairly "unique" I'd start with one of the free 2D CAD packages

Hub Cam Solutions D3 Technologies

Milling Machining Wikipedia

25D animation is a 2D animation drawn into a 3D space as it involves the motion of 2Danimated object in a 3D space The trick lies behind the perspective and shadows of 2Danimated objects drawn in 2Dspace that appears to be 3D Animators use the impression of drawing 2D objects in motion that appears to be moving in a 3D space accomplished by using brilliant art skills inSolving 3d 2 5d2 = 0 directly Earlier we factored this polynomial by splitting the middle term let us now solve the equation by Completing The Square and by using the Quadratic Formula Parabola, Finding the Vertex 41 Find the Vertex of y = 3d 2 5d2 Parabolas have a highest or a lowest point called the Vertex25D is where you cut out 2D shapes in one or multiple passes to a set depth It's basically a way to simulate a 3d look without all of the complex calculations that go along with a true 3d toolpath A good example is Vcarving 3D is where the shape or feature you are

Complete Guide To Cam Toolpaths And Operations For Milling In

1

Basically, 25D is where two axis (XY) are interpolated to cut a detail at a fixed depth, then Z in stepped to the next depth and the next profile is cut, and so on till the part is done this gives a steps and stairs look to the part 3D is where all 3 axis are interpolated to give a smooth 3 dimensional contour to the part The Japanese brand, wellknown for its famous watches, is exploring a new print technology, called 25D printing As its name suggests, this print technology lies somewhere between 2D and 3D printing The 25D printing technology adds a tactile dimension to 2D printing, allowing users to touch and feel the surface and texture of the printed object The case for 25D If you're just starting out in CNC, it's probably best to start with 25 D instead of 3D for modeling I say this because 3D modeling generally has a longer learning curve For the novice in CNC, there's enough to learn already, so it makes sense to me to start simpler with tools that are easier to learn and to get working

2d Vs 2 5d Vs 3d Robocnc Frees Graveerwerk

What S The Difference Between 3 Axis 4 Axis 5 Axis Milling Cloudnc

is MC mill level 3 25D milling or 3D milling program In V8 & V9 there were some basic multiaxis tpaths that were part of the Mill3 license Reading further, the issue appears to be some confusion regarding the difference between a gantry router (25D) and milling machine (3D or higher)You can best explain this by looking at the cutting result 2D cutting 2D cutting is simply the cutting of contours from a material With 2D cutting, the cutting head from which the water jet comes does not change

Fikus Visualcam Cad Cam Software For 2d 2 5d 3d Milling

2 5d Milling Of Planar Surfaces Contours And Pockets

The 25D model is what we generate to do the orthophoto since it is being drawn from directly above (that is the ortho part) and it has no information about overhung areas The full 3D model has the undercut areas under the points of the main axis of the pavilionMilling different materials – 3D and 3D milling With our CNC machines, you can mill almost all materials in 2D and 3D In this area, we show you some applications of milling aluminium, wood and plexiglass with excellent accuracy Create patterns of drilling, make drafts for your workpieces or create 3D contoursIt's not 3D It's not 2D It's 25D!If you want more sources on learning this stuff, then here are some places you can go toWikipedia https//enwikipedia

2d Vs 2 5d Vs 3d Robocnc Frees Graveerwerk

Condacam 2 5d Milling

In the process of machining, the 25D mainly refers to the particular surface that is considered as the projection of a plane into 3rd dimension – although the object is 3dimensional, there are no overhanging elements possible25D vs 3D So far we have only created what are called 25D models, simple extrusions of a crosssection The techniques we learn today will allow us to create "true" 3D models Taper Extrude Simply adding a taper angle to your extrude command can give you interesting volumes Tapered extrusion Tapered extrusion CAD Features and TipsIn CNC the difference between 25D and 3D is that true 3D can SIMULTANEOUSLY move three axis for instance go from x1,y1,z1 to a x2,y2,z2 all axis moving at the SAME TIME 25d only allows that in X and Y to move simultaneously but all movements of Z are done by itself and not at the same time that X and Y move 15K views

Shopsabre Operation And Safety Ppt Download

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

Very well suited to 3D milling, but a lot less nice for 25D, which you tend to do a lot with a 130x245x9 machine To everyone swearing by On the other hand, making complex 3D objects is a lot more complicated with CNC milling than with a 3D printer There are free tools for doing 25D milling, but CAM software for 3D milling can be very expensive and difficult to use Doing 3D work for 3D printing is much easier2D vs 25D vs 3D Carving Part 36 Aspire and VCarve For Absolute BeginnersMore down here ↓↓↓ Click SHOW MORE!This is the 36th in a series of videos geare

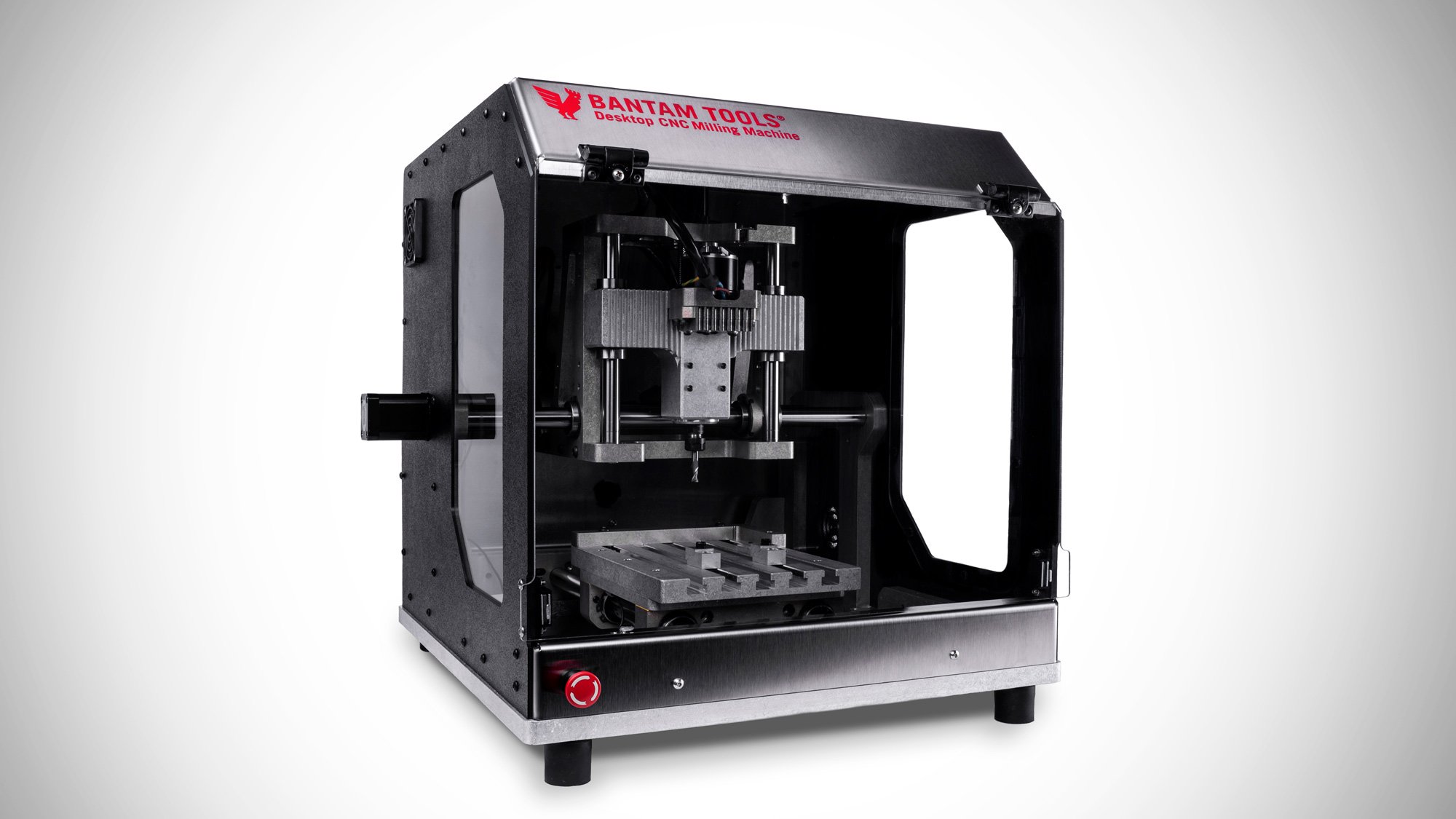

New Bantam Tools Desktop Cnc Milling Machine Is Aimed At Prototypers

Computer Aided Manufacturing Wikipedia

3D CAM Toolpath Fundamentals Please welcome Robert Grzesek, founder of GRZSoftware and author of MeshCAM 3d cnc cam software for this guest post on the fundamentals of 3D milling toolpaths in CAM Robert's forte, aside from creating wonderful software like MeshCAM, is making very complex topics easy to understand free 3d modeling software sketchup,blenderlow cost 3d modeling software design cad 3d,alibre is a good software ,linuxcnc is free download I use it to run my sherline 3 axis cnc mill ,linuxcnc is easy to install and use also mach 3 is good for about 0, I use solidedge which i have been using fo about 10 years but it is not cheap,you could try taking some classes in 3d modeling 25D, or "two and a half dimensions", is a graphics or image terminology with different meanings In the art and animation industry, 25D is a technique widely applied in animation and video games In otaku culture, 2D means the realm of fiction while 3D

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

Cnc Machining The Manufacturing Design Guide Hubs

Bloodstained is unless I'm mistaken made in UE4 UE4 and Unity are both 3d engines that can make fully 3D games (or 25d games) but also have lots of tools and support in them to make completely 2D style games as well If I had to guess I'd guess that the spinoff game was made in the same engineAlways fun to get an A on an older question Thanks In regards to computer modeling, and not CAM/CNC machines 2D "modelling" is using a 3D(or more) capable modeling program as a flat two dimensional CAD/drawing tool This may be something likeIMachining 2D Toolpath By clicking, you agree to load the video More information

Tech Breakdown Carbide 3d S Nomad 8 Pro Matterhackers

6090 Cnc Router 2 5d Machining With Stuff Ups Youtube

Most CAM programs support 25D milling Vectric Cut 2D and V Carve do a great job 3D milling refers to the CNC's ability to move X, Y and Z all at the same time in a synchronized fashion to create contoured bottoms, sides and tops of objects Many times this will be called 3D carving of material The terms 2D and 3D (as you probably already know) refer to the number of spatial dimensions in a Euclidean worldspace This dimensionality must be an ordinal number;2D graphical projections and similar techniques

China 2 5d 3d Milling Machine Tool Changer Cnc Carving Machine Manufacturer For Polishing Drilling Milling Chamfering Cutting Grinding Carving Engraving Photos Pictures Made In China Com

1

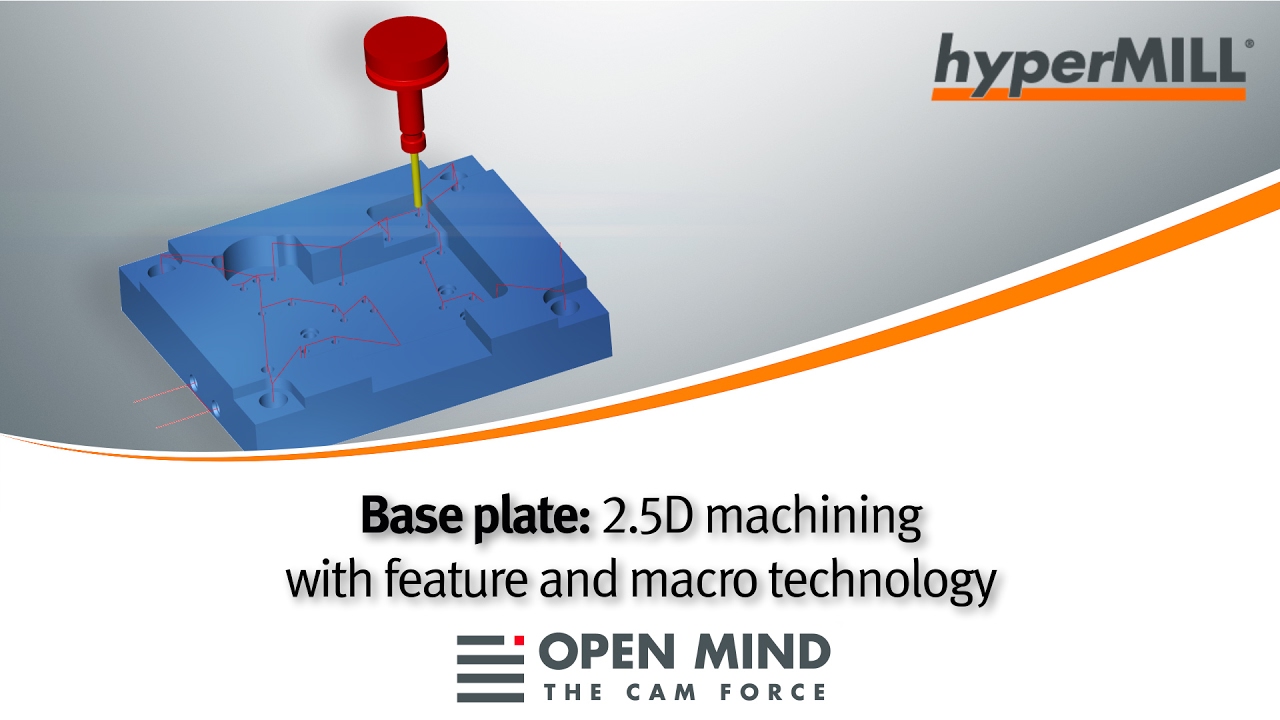

HyperMILL ® 25DStrategies Chamfer Milling on 3D Model Did you know how fast and easy the deburring and chamfering can be programmed with hyperMILL ®?Here are a few suggestions The stepover should be between 1/3 and 1/10 of the tool diameter Use a larger stepover, in the 1/5 to 1/3 range, for soft materials that cannot hold detail well Use a smaller stepover, in the 1/5 to 1/10 range, for hard materials or materials that can hold significant detail like metal and jewelers waxA bit, or end mill, is mounted to the spindle (the spinning part) The bit is lowered slowly till it comes in contact with the stock material And material is removed 25D vs 3D Working in two and a half dimensions (25D) means you are cutting a part that has multiple

Toolpaths Shapeoko Cnc A To Z

Hsmworks 16 Cam Family Released Digital Engineering 24 7

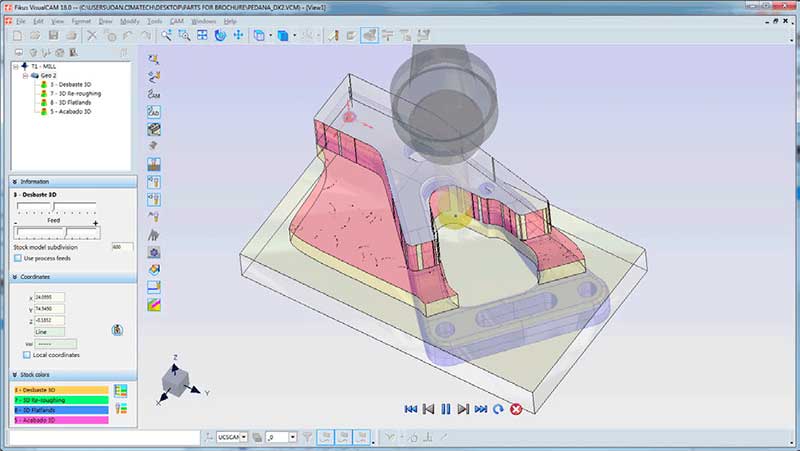

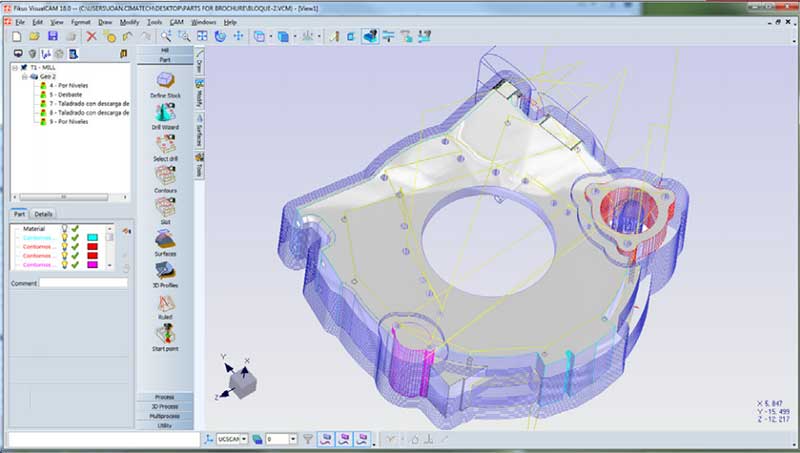

2D Versus 3D in CADCAM Software CNC Machine Programming Posted 337 pm Published by Al DePoalo BobCADCAM CADCAM software has everything to do with modern CNC machine programming and plays a critical role in the future success of manufacturing at a global level Manufacturers are continuously looking for solutions toFikus Visualcam Milling module is a powerful yet easy to handle CAD/CAM for milling production jobs It comes with all necessary functions to machine wireframe 25D and complex 3D surfaces, included advanced optimization options as roughing, prefinishing, finishing, flat areas machining, residual areas or bitangenciesGranite Base Construction Acoustic Cabinet 15 Piece Auto Tool Change Motorized Z Axis Vacuum Table with Ceramic Plate Fiducial Camera 25D Pocket Milling

Solidcam Cam Software 2 5d Milling

Toolpath Planning

25D (twoandahalf dimensional, alternatively pseudo3D or threequarter) perspective refers to one of two things Gameplay or movement in a video game or virtual reality environment that is restricted to a twodimensional (2D) plane with little to no access to a third dimension in a space that otherwise appears to be threedimensional;A 25D image is a simplified threedimensional (x, y, z) surface representation that contains at most one depth (z) value for every point in the (x, y) plane References edit ^ 25D and 3D Machining , archived from the original on , retrieved25D is a packaging methodology for including multiple die inside the same package The approach typically has been used for applications where performance and low power are critical Communication between chips is accomplished using either a silicon or organic interposer, typically a chip or layer with throughsilicon vias for communication While communication between chips

Solidcam Cam Software 2 5d Milling

Pdf Cnc Programming Of Pocket Machining

2,5D milling have ramping and helical movement as well The limitation is that 2,5D could not mill with a calculated gauge pass a 3D surface or have the strength of different 3D strategies To mill pass a 3D profile is possible (line, arc, spline in 3D), but not follow a 3D surface with defined overlap

Solidcam Cam Software 2 5d Milling

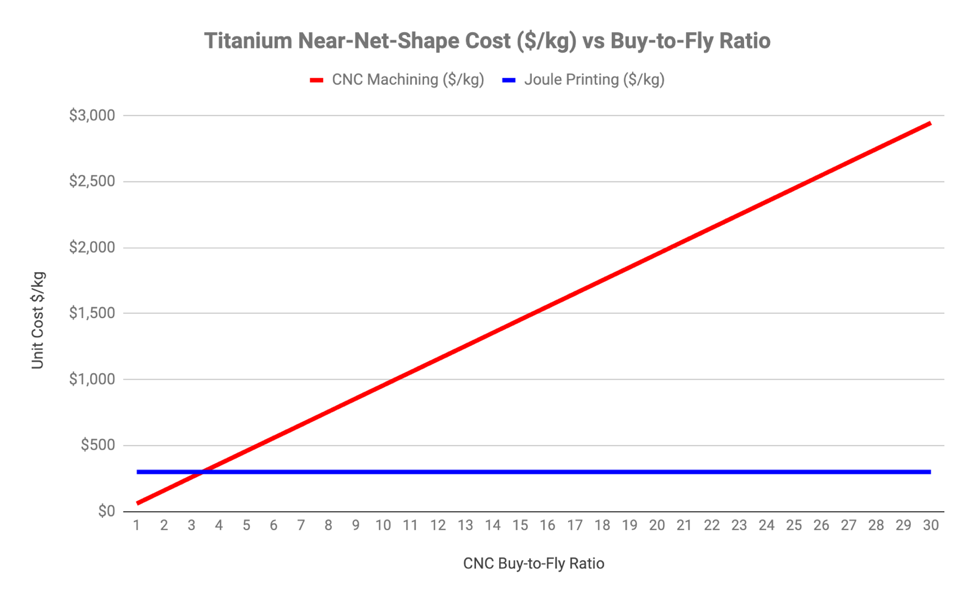

Comparison Of Additive Manufacturing Cnc Machining Digital Alloys

Fikus Visualcam Cad Cam Software For 2d 2 5d 3d Milling

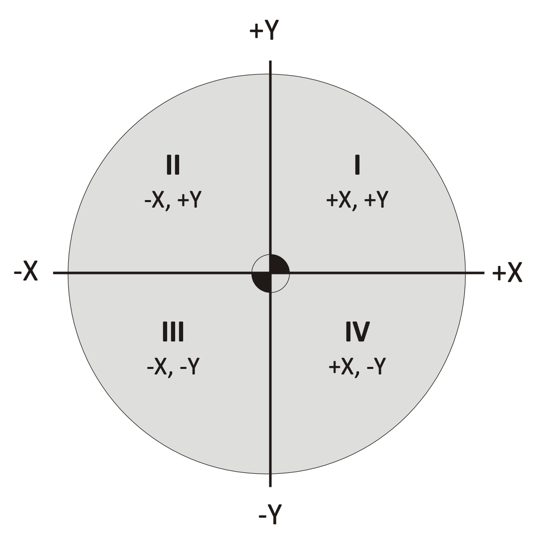

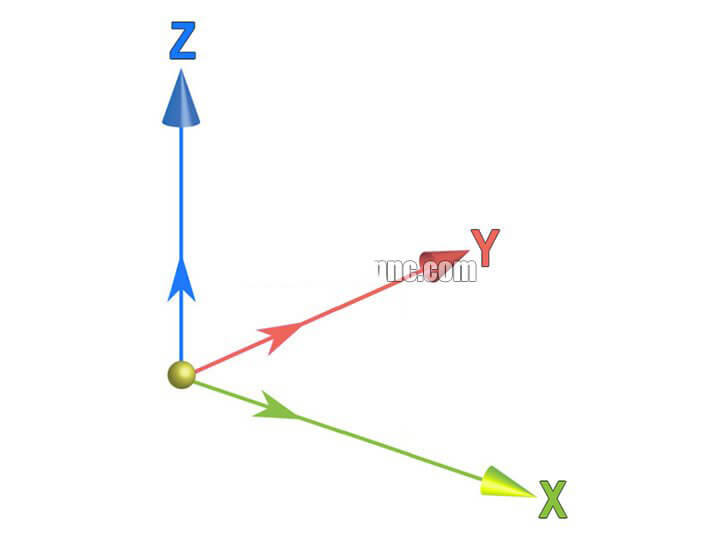

Cnc Milling Coordinate System Made Easy Fusion 360 Blog

Fab Academy Site

Week 10 Cam Itp Fabrication

Big Cnc Studio Colinbus 3d And 2 5d Milling Machine Flickr

What S The Difference Between 3 Axis 4 Axis 5 Axis Milling Cloudnc

New Bantam Tools Desktop Cnc Milling Machine Is Aimed At Prototypers

43 2 5d Cnc Furniture Ideas Cnc Furniture Furniture Design

China 2 5d 3d High Precision Cnc Machine For Polishing Drilling Milling Chamfering Photos Pictures Made In China Com

2 5d Cnc Mill Youtube

Fab Academy Site

Solidcam Cam Software 2 5d Milling

Best Cad Cam Software 21 List Of The Best Systems

Shopbot What Is Cnc

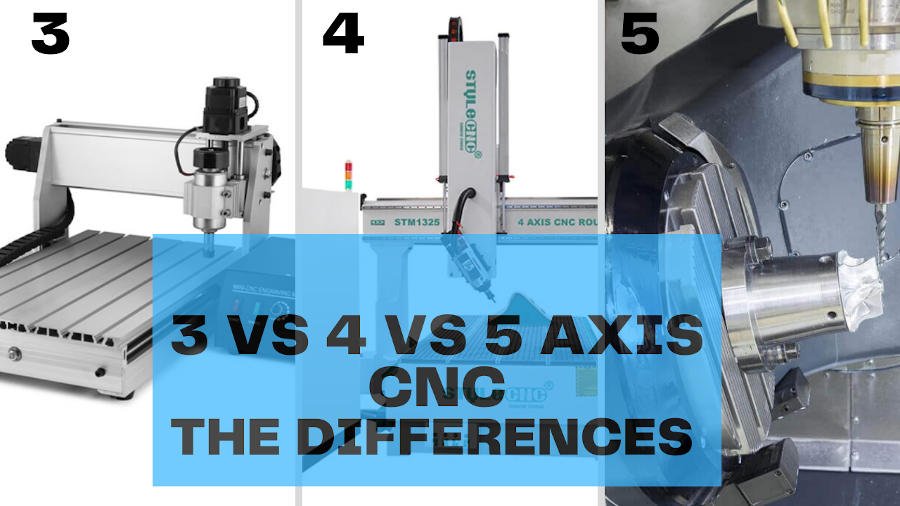

3 Axis 4 Axis 5 Axis Cnc What S The Difference Which Is Best Cncsourced

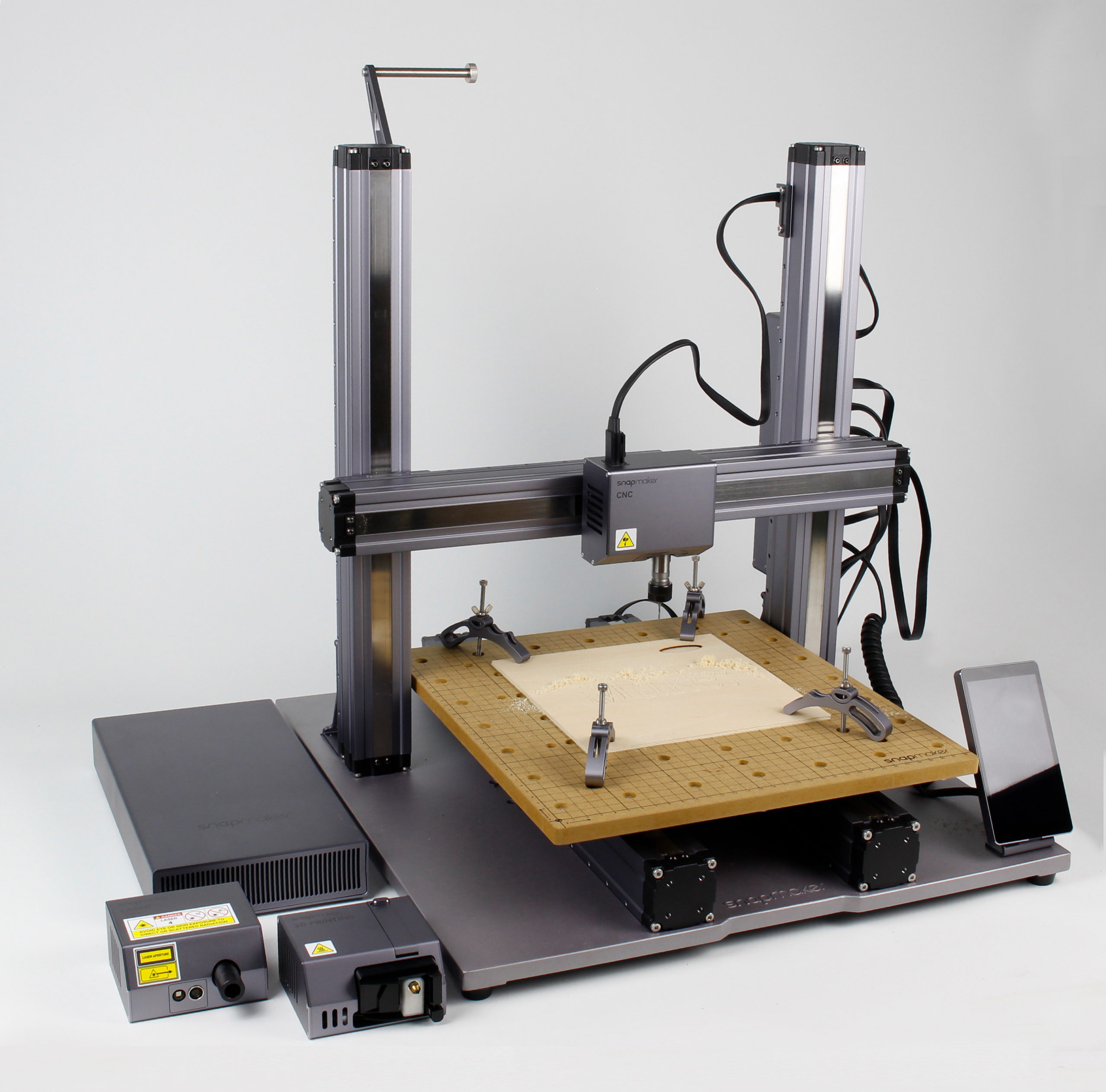

Snapmaker 2 0 A Hands On Review Make

Solidcam Cam Software 2 5d Milling

Milling 3d 2 5d Shapes In Mdf Extended Youtube

Cnc Machining Vs 3d Printing Make

Shopbot What Is Cnc

Integrated Cam Software Cadpro Systems

Shopbot What Is Cnc

Camconcept Emco Lathes And Milling Machines For Cnc Turning And Milling

Solidcam Cam Software 2 5d Milling

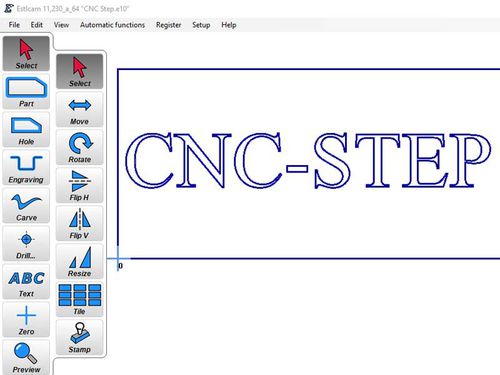

Estlcam 2d 2 5d 3d Cam Software

Some Simulation Results From Left To Right 2d Milling 2 5d Lathe 3d Download Scientific Diagram

China 2 5d 3d High Precision Cnc Machine For Polishing Drilling Milling Chamfering China Precision Cnc Machine Engraving Machine

Cam Software Estlcam Cnc Step Gmbh Co Kg 3d Cnc Router Engraving Programming Interface Control

First Attempt At 2 5d Routing Cnc

Hypermill 2 5d Strategies Chamfer Milling On 3d Model Cam Software Youtube

Computer Aided Machining Cam Software For Programming Cnc Machines Ppt Download

It S Not 3d It S Not 2d It S 2 5d Youtube

Universal 2 5d And 3d Machining For High Hard Steels With Fraisa Xspeed H Youtube

What Is 2 5 Axis Cnc How It Is Different From 3 Axis Machine

Best Cam Software For Solidworks Autocad Co All3dp Pro

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

Inventorcam Milling Training Course 2 5d Milling Ppt Download

Digital Fabrication Studio Cnc Milling

3 4 5 Axis Machining What Is The Difference Inverse

3 Axis Vs 4 Axis Vs 5 Axis Cnc Mill Ultimate Guide Taicnc

3 Axis Vs 4 Axis Vs 5 Axis Cnc Mill Ultimate Guide Taicnc

Affordable 3d Cnc Routers 3d Cnc Machines For Sale Stylecnc

For Milling 2d 2 5d 3d With The Cnc Editor Or Directly Send It To The Machine Other Functions Pdf Document

Bantam Tools Desktop Cnc Milling Machine Specs Price Release Reviews All3dp

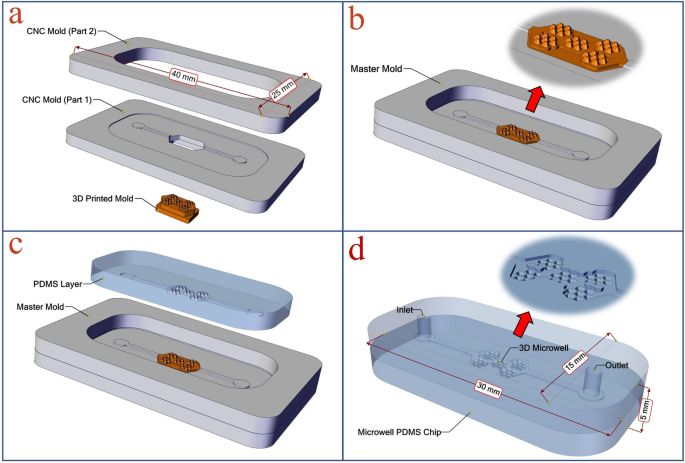

A Combined 3d Printing Cnc Micro Milling Method To Fabricate A Large Scale Microfluidic Device With The Small Size 3d Architectures An Application For Tumor Spheroid Production Scientific Reports

Cnc 2 5d Axis Vs Virtual Cnc

8 Computer Controlled Machining Fabrication Embedded Technology Textiles Biology Design

Comparison Of Additive Manufacturing Cnc Machining Digital Alloys

21 Best Cnc Routers For Aluminum Stylecnc

How Are Physical Models Created From 3d Designs Shapr3d Help Desk

3d Vs 2 5d Is It Well Defined The Shapeoko Forum

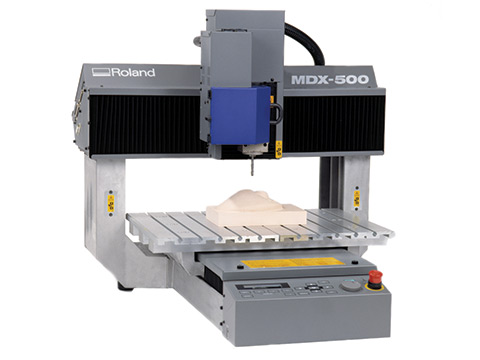

Modela Mdx 40a 3d Milling Machine Roland Dga

Comparison Of Additive Manufacturing Cnc Machining Digital Alloys

China 2 5d 3d Milling Machine Tool Changer Cnc Carving Machine Manufacturer For Polishing Drilling Milling Chamfering Cutting Grinding Carving Engraving China 2 5d 3d Tool Changer Milling Machine Cnc Carving Machine Manufacturer For Polishing

An Introduction To Cnc Machine Control Hackaday

Modela Mdx 40 3d Milling Machine Roland Dga

Cnc Machining 2 5d Machining With Feature And Macro Technology Hypermill Cam Software Youtube

2d 2 5d Milling Cam Software Open Mind

2d 2 5d Milling Cam Software Open Mind

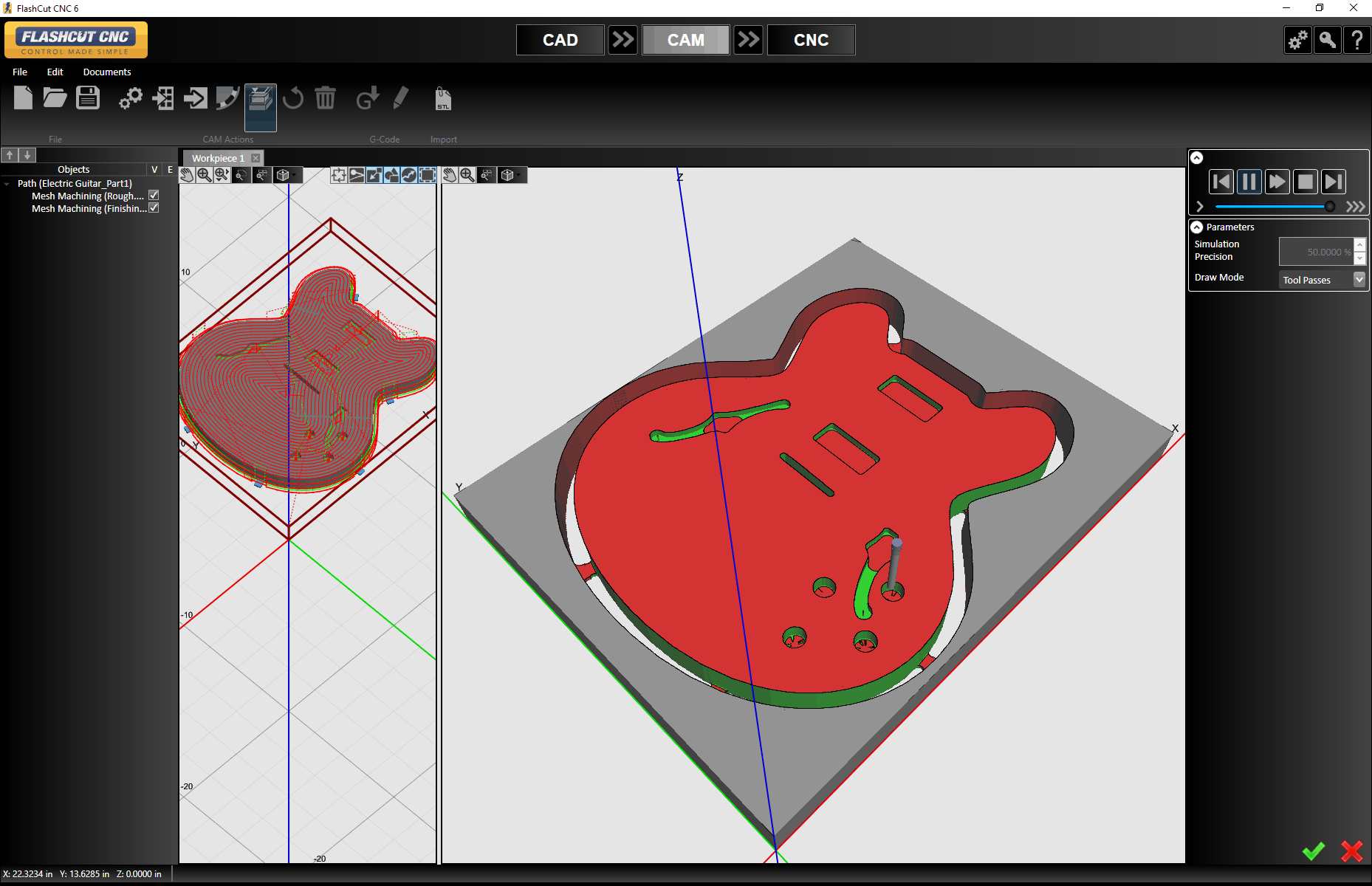

Flashcut 2 5d 3d Cad Cam Cnc V9 Pro For Mills Routers Flashcut Cnc

Cam Tool Global 3dcam 2dcam Hole

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

Cnc Machining The Manufacturing Design Guide Hubs

1

New Bantam Tools Desktop Cnc Milling Machine Is Aimed At Prototypers

2d Vs 2 5d Vs 3d Robocnc Frees Graveerwerk

Manufacturing Features 2 5 And 3 Axis Milling Youtube

Toolpath Planning

Cnc Machining The Manufacturing Design Guide Hubs

1

Powerful And Affordable Cam Software Bobcad Cam

Robotics Vision At A Glance The Dos Don Ts And Applications

3d Cnc Desktop Machine For Engraving Comagrav Mt Profi Comagrav

Introduction To 2 5d Milling 5 Steps Instructables

Modela Pro Mdx 500 3d Milling Machine Roland Dga

Cnc Milling Coordinate System Made Easy Fusion 360 Blog

0 件のコメント:

コメントを投稿